The countdown to zero begins with our newest zero-emission hydrogen projects

HYDROGEN

Our hydrogen

projects

We're excited to introduce our hydrogen investments! Each of our projects bring us one step closer to reaching our zero emissions goal. Read on to learn more about how our hydrogen investments are helping us make the world a cleaner and greener place!

Our Long Ridge project

We’re proud to be powering a greener world with our first zero-emission hydrogen project. Through our Zero division, we’ve partnered with Long Ridge Energy Terminal and GE Gas Power to help transition Long Ridge’s 485 MW combined-cycle power plant in Hannibal, Ohio, to run on carbon-free hydrogen. Today, we’re blending hydrogen into the natural gas that fuels the plant at Long Ridge. Over the next decade, we will work with GE to transition the plant to run on 100% hydrogen. Our Zero division will further support the transition by scaling up novel technologies that can produce low-cost zero-emission hydrogen.

Long Ridge is the country’s first purpose-built hydrogen-burning power plant and the world’s first to blend hydrogen in a GE H-class gas turbine. The plant’s GE 7HA.02 combustion turbine can initially burn from 15% to 20% hydrogen by volume in the gas stream, and can transition to 100% hydrogen over time. Black & Veatch has helped design and execute the plant’s integration for hydrogen blending to ensure safe and reliable industrial practices.

We’re proud to be putting positive energy behind our Long Ridge project, and we’re excited to take our first step toward reaching our ambitious zero emissions target with carbon-free hydrogen.

Our H2Pro partnership

We’re also seeking better ways to produce green hydrogen from the start. Through our investment in H2Pro, our Zero division will support demonstration projects and commercialization of this innovative partner’s novel, efficient, low-cost green hydrogen production technology.

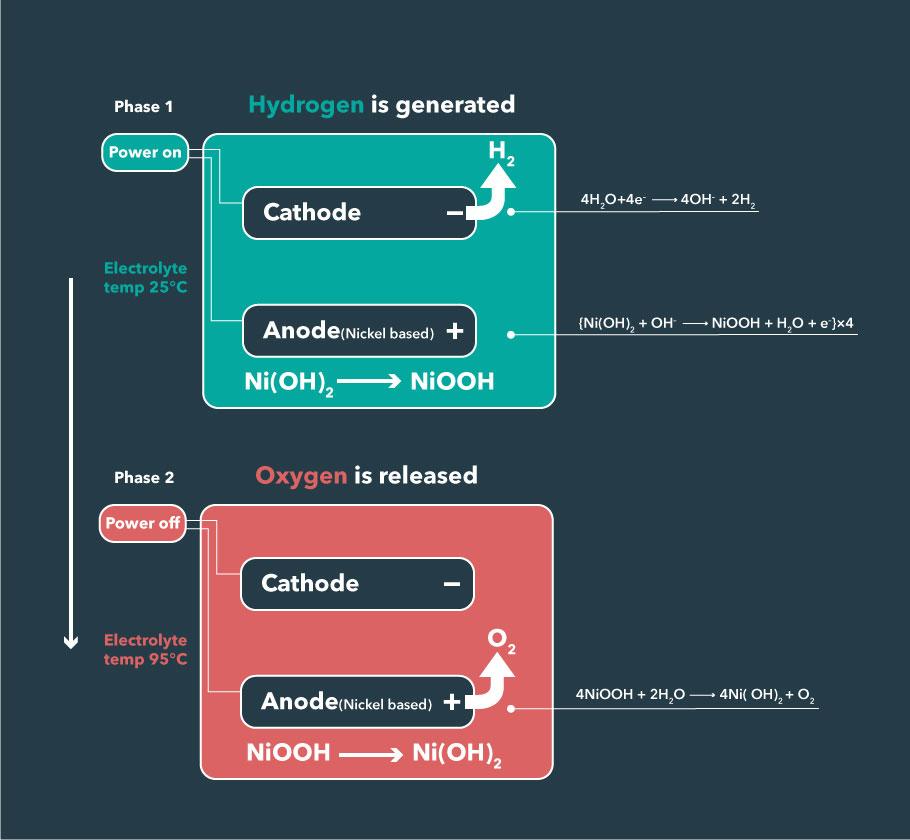

H2Pro’s E-TAC (Electrochemical-Thermally Activated Chemical) technology uses renewable energy to split water into hydrogen and oxygen in two phases. Created by scientists at the Technion - Israel Institute of Technology, this 95%-efficient process produces hydrogen using nearly 30% less renewable electricity than other leading electrolysis technologies.

H2Pro is designing modular, scalable systems that are less reliant on electricity, are membrane-free, don’t require precious metals, and can operate at high pressure, dramatically reducing production costs.

This collaboration shows strong promise in enabling the use of hydrogen as the gold standard, zero-emissions alternative to fossil fuels. It’s a great example of how less can truly be more.

Our Zero Parks joint venture

Just a year after we formed our Zero division with the ambitious goal of reaching net zero carbon emissions, we’re excited to be making a significant commercial investment in the clean energy space. Zero Parks combines our focus on hydrogen and experience providing cleaner energy with the transportation expertise and U.S.-based high-utility terminal and port infrastructure of our joint venture partner, Fortress Transportation and Infrastructure. Together, we intend to commercialize the rapidly growing opportunity for renewable and low-carbon fuels.

Today, most of the 51 billion tons of greenhouse gasses – including 37 billion tons of CO2 – emitted into the atmosphere every year comes from fuel consumption. Less than 1 percent of the fuels being used are either renewable or clean. To accelerate the transition of that other 99 percent of the market to greener alternatives, Zero Parks will create clean energy hubs focused on low-cost production of two powerful solutions:

- Renewable, fossil-free, fuels made from recycled, repurposed materials such as vegetable oils, animal fats, used cooking oils, and other biomass. While these do still emit CO2 when burned, they also recycle waste and avoid extracting additional fossil fuels.

- Clean, hydrogen-based fuels such as blue ammonia, which traps the CO2 from traditional fossil fuel production, preventing its emission, while providing a fresh source of hydrogen for entirely carbon-free energy.

We’re thrilled to be taking this major step on our journey to light the world with zero-carbon power.

Our projects in the news

-

In the news

NFE enters agreement with Plug Power for 120 MW green hydrogen plant on Gulf Coast

-

In the news

Israeli green hydrogen start-up attracts Bill Gates fund

-

Hydrogen

HydrogenLong Ridge Energy Terminal partners with New Fortress Energy and GE to transition power plant to zero-carbon hydrogen

-

Hydrogen

HydrogenNew Fortress Energy invests in green hydrogen production technology company H2Pro