The greenhouse is always greener with liquefied natural gas

LNG CASE STUDY

Silver Vase goes green – and saves green

When you think of the delicate beauty and exotic fragrance of orchids, dirty propane and diesel fuels shouldn’t be part of the picture.

Silver Vase, a wholesale floral supplier, agrees. That’s why this major provider of premium orchids – serving big box retailers and grocery store chains throughout the U.S., Central America, and the Caribbean – decided to nip the situation in the bud. Over the past four years, Silver Vase has partnered with New Fortress Energy (NFE) to convert both its boilers and its backup power generation system at its primary greenhouse in Homestead, Florida, to liquefied natural gas (LNG).

Sowing the seeds of a ‘clean and green’ operation

Each year, Silver Vase’s Homestead operation blooms with 5 million orchid plants – and each and every one has to be kept at the same strict and steady temperature to maintain its premier quality and freshness. The three boilers that control the temperature and monitor the humidity had historically operated on diesel and propane. However, in 2017, Silver Vase partnered with NFE to reduce its costs and its environmental footprint by converting its operation from these dirtier and more costly fuels to natural gas.

NFE’s turnkey solution is providing a more reliable, cleaner, less expensive fuel source so Silver Vase can maintain "clean and green" plants for its customers. NFE converted the three boilers to run on liquefied natural gas (LNG), and installed four 500-kilowatt natural gas generators plus 14,000 gallons of onsite liquefied natural gas (LNG) storage.

Completed on time in just five months, with zero downtime, the project now delivers liquefied natural gas (LNG) filled ISO tanks from NFE’s Miami plant to the Homestead greenhouse.1 Liquefied natural gas (LNG) deliveries arrive every 10 to 15 days in the summer, and every 5 to 7 days in the winter when the flowers need some extra-warm TLC.

Getting to the root of the complete power solution

The site’s South Florida location, with its higher risk of tropical storms and hurricanes, makes having a reliable backup power solution imperative – without it, millions of orchids would quickly perish. About a year after it partnered with NFE to convert its boilers, Silver Vase extended the collaboration, entrusting NFE to handle all its power needs and convert its backup power generation system to natural gas as well.

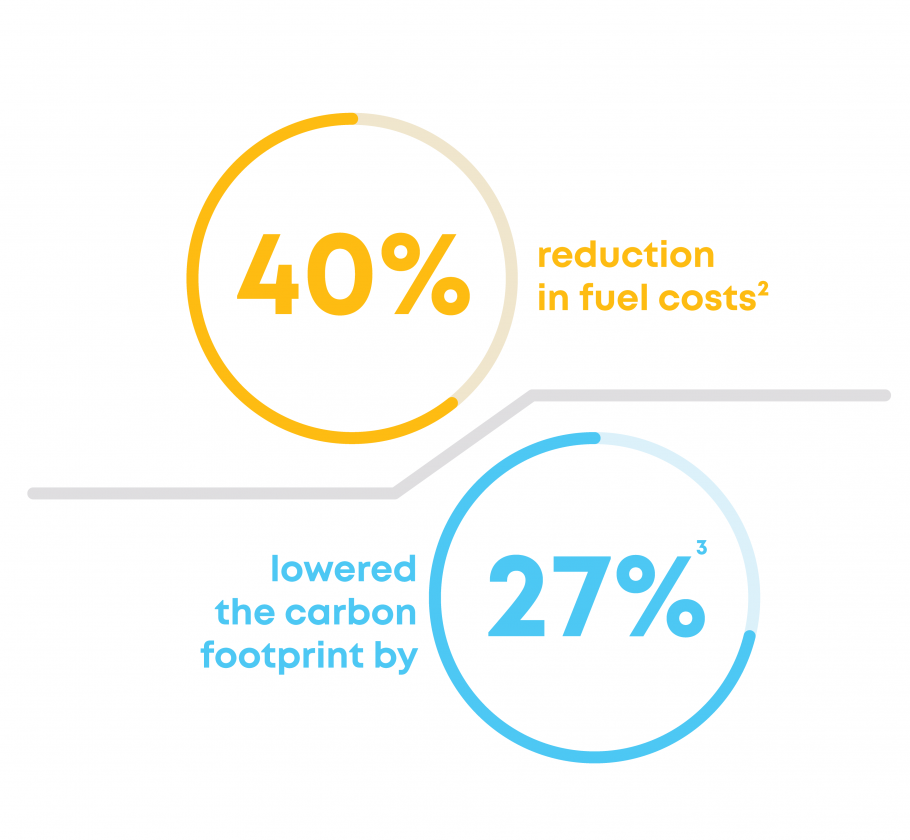

The complete new system has reduced fuel costs by 40 percent, and lowered the carbon footprint by about 27 percent.2,3

It just goes to show that, when it comes to keeping operations green, it’s vital to keep exploring beyond garden variety solutions – and don’t stop be-leafing that you can make a meaningful difference with positive energy.